FEATURE

-

Fe removal

Mn removal

NH4+-N removal equipment -

No Chemical Injection

-

Simple

operation

Watch with video(Company profile movie 2:27-3:10)

FeMnNH4+-N

Can treat Fe, Mn, and NH4+4+N contained in groundwater chemical injection.

(Results: Fe 40 mg/L, Mn: 4 mg/L, NH4+-N: 6 mg/L)

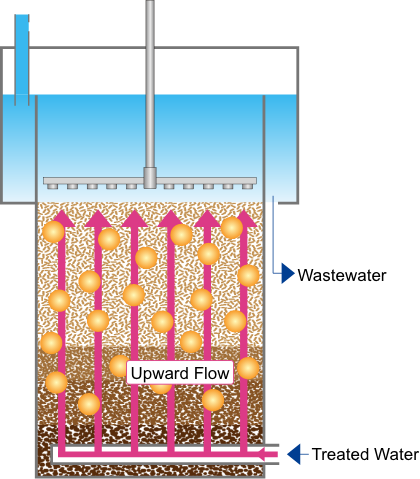

Materials that exceed drinking water standard, such as Fe, Mn, and NH4+-N, are contained in groundwater. Generally, the coagulation-sedimentation method or rapid filtration method, which use chemicals such as coagulation and chroline. However, chemicals must be managed, and it is difficult to treat the water when there are high concentrations of Fe, Mn, or NH4+-N.

No Chemical Injection

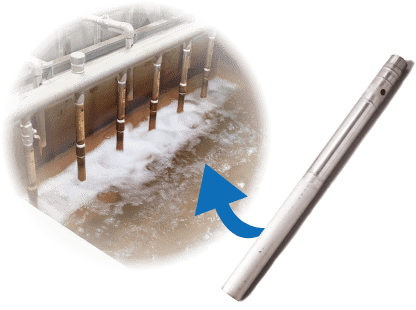

Special oxidation nozzles

Our special oxidation nozzles put the dissolved oxygen concentration into a saturated state. This facilitates the oxidization of Iron and Manganese in an ionic state, and also promotes Ammonium nitrification reactions. These nozzles utilize pressure from raw water, so they are more economical and have a smaller environmental impact than conventional aeration systems.

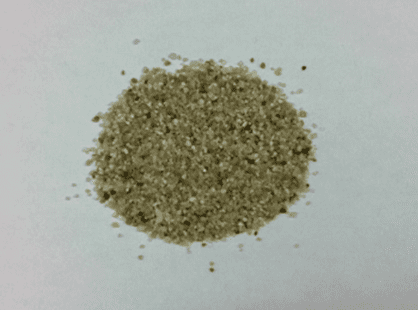

CHEMILES contact media

A natural coat is formed to improve the treatment performance.

-

New contact media (silica sand)

-

-

Formation of iron oxide, manganese oxide coating.

After acclimation is completed:

・No adjustment is necessary for changes in raw water quality (seasonal etc.).

・Biological treatment is employed at the same time, but a stable treatment performance can be utilized even in cold regions and during winter.

Simple operation

POINT1No requirement for chemical management

POINT2No requirement to change contact madia

POINT3Fully automated operation

Suitable for operation in locations with few staff, such as small waterworks.

-

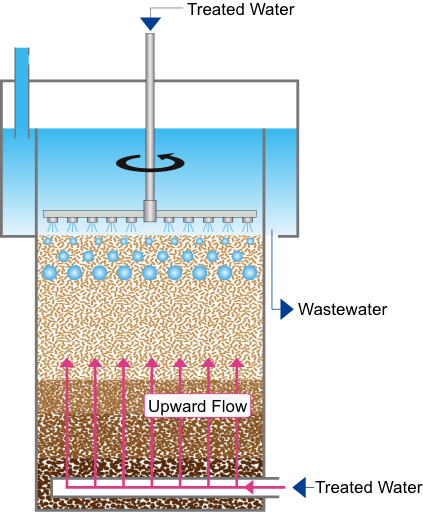

P Backwash

P (Portion) Backwash is for cleaning of upper part of filter media (iron removal layer), which is at 100~400 mm from the surface.

-

W Backwash

W(Whole) Backwash is an intensive backwash to entirely clean filter media. W Backwash is operated at an optimum frequency to avoid damage to the catalytic manganese dioxide and biological films formed onto the filtration sand.

Nagaoka’s unique cleaning technology enables maintenance-free, fully automatic operation while maintaining constant processing performance.