CHEMILES treats groundwater to the drinking water level without the use of chemicals.

Groundwater may contain iron, manganese, ammonium nitrogen, etc., which are harmful to human body. Therefore, drinking water requires to remove those harmful substances to a certain level although large amount of chemicals are used in conventional method. CHEMILES is a safe and effective solution to remove all these harmful substances without chemicals

Small infiltration area

LV=500m/day

Ultra-High Speed TreatmentStable treatment performance

WP Washing

Reduce the risk of creating harmful substance and environmental impact

No Chemical Injection

Removal of high concentration substances

Iron 40mg/L

ArsenicRemoval of high concentration substances

Ammonium nitrogen

Manganese

Extremely high treatment speed

Approximately 100 times faster than conventional biological treatment system

4 times faster than typical chemical treatment system.

Minimal space required for the system due to high rate of treatment

Reduction of running cost

Cost for chemical and personnel of chemical control is unnecessary.

Our patent technology “WP Washing” is automatically controlled by programming.

Typically, no adjustment is necessary for changes in raw water quality (seasonal etc.).

Sand filter media can be used semi-permanently.

Environmental friendly

No industrial waste from use of chemical is produced.

No chemical residue provides safe and reliable drinking water, as well as easier application to industrial water.

| Conventional chemical treatment system | CHEMILES | |

|---|---|---|

|

Necessary (It requires great amount of cost) | Unnecessary |

|

Generated (It requires treatment cost) | None |

| Filtration speed | LV=120m/d | LV=500m/d |

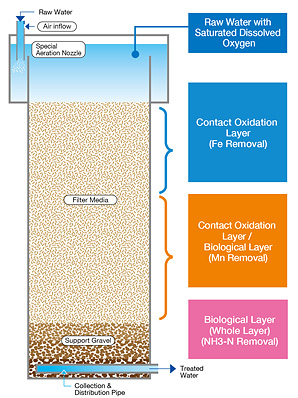

Mechanism of CHEMILES

“WP Backwash” for Maintaining

Stable Performance

W Backwash

W(Whole) Backwash is an intensive backwash to entirely clean filter media.

W Backwash is operated at an optimum frequency to avoid damage to the catalytic manganese dioxide and biological films formed onto the filtration sand.

P Backwash

P (Portion) Backwash is for cleaning of upper part of filter media (iron removal layer), which is at 100~400 mm from the surface.

Data Shows the Outstanding Performance of CHEMILES!

-

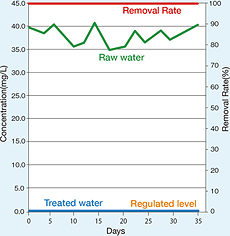

Iron Removal

-

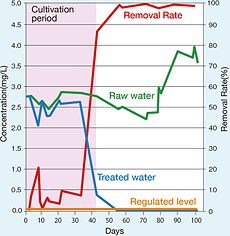

Manganese Removal

-

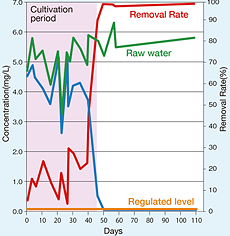

Ammonia Nitrogen Removal

- *Cultivation period ... 2 to 5 months (vary with the quality of raw water)

- *The period until nitrification by nitrifying bacteria and formation of catalyst membrane (e.g. manganese dioxide membrane) deliver the required performance.

-

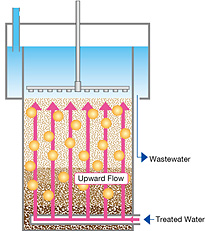

Outdoor Column Type

“Non-chemical injection”, “biological treatment” and “extremely high speed filtration” are the remarkable features of CHEMILES and the key factor for its successful production of safe and reliable water.

Outdoor Column Type can be installed outdoors and in limited space, and is commonly used in commercial facilities for food processing, linen industry, hospitals and so on. -

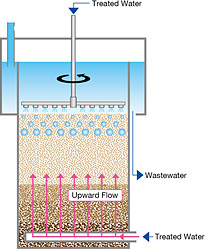

Open Top Type

Open Top Type is the original design of CHEMILES and has been installed mainly in domestic water purifying plant. CHEMILES is grand sum of NAGAOKA’s water treatment technology and has been performing high treatment capacity in an environmentally conscious manner. Our rich experiences are contributing to sustainable water supply.

-

Reinforced Concrete Type

CHEMILES Reinforced Concrete Type is suitable for large-scale water treatment plants which require economical solutions. The first installation was in China and the demand of Reinforced Concrete Type is increasing not only in China but also among Asian countries where the needs for “clean water” is rapidly glowing.

-

Shen Yang Shi, Shen Bei Xin Qu, China

-

Sui Hua Shi, China

-

Hanoi, Vietnam

-

Pilot Test in U.S.A.

-

Malaysia

-

M-City, Japan

-

H-City, Japan

-

T-City, Japan

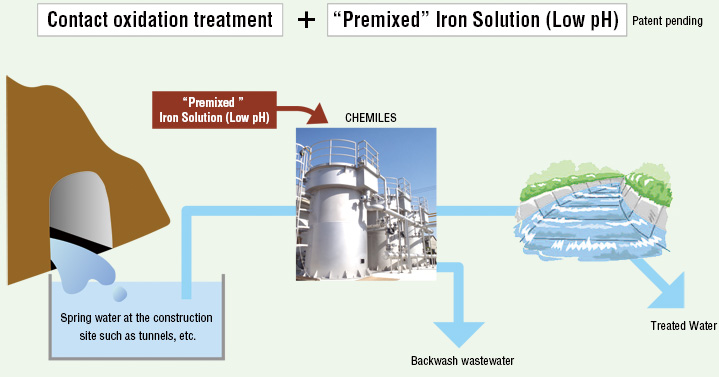

Nagaoka Arsenic Removal Technologies

1.Significant Initial Cost Reduction

High-speed treatment sharply reduces system foot print, hence reduces initial cost.

2.Significant Running Cost Reduction

Efficient arsenic removal method cut down chemical usage of the conventional technology to 1/3 to 1/10.

3.Simple Maintenance

Automatic operation enables no chemical management and simple maintenance.

4.Significant Waste Reduction

By reducing usage of chemicals, less sediments and sludge are formed during the treatment. Waste is only from sludge in backwash wastewater.

Comparison with conventional coagulation sedimentation treatment system

Case of treating 400 m3/h (9,600 m3/d) of spring water

| Contents | Nagaoka’s Technologies (Contact oxidation and Co-precipitate) |

|---|---|

| Installation Area | Approximately 35% reduction |

| Initial Cost | Approximately 30% reduction |

| Running Cost | Approximately 15% reduction |

(Estimated by NAGAOKA)